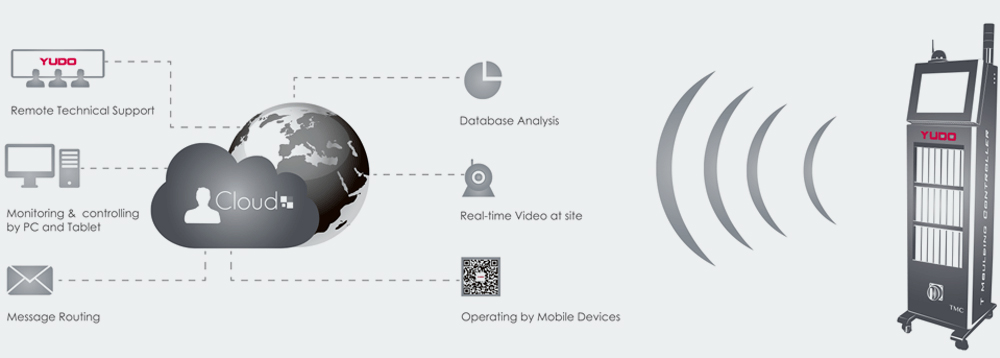

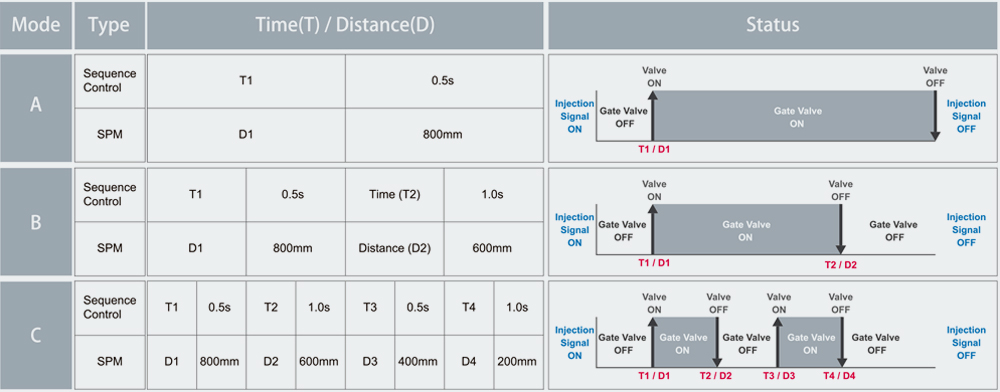

1. TMC is a controller that integrates temperature control, timing control, and cloud server Internet of Things;

2. Compact body design, small footprint;

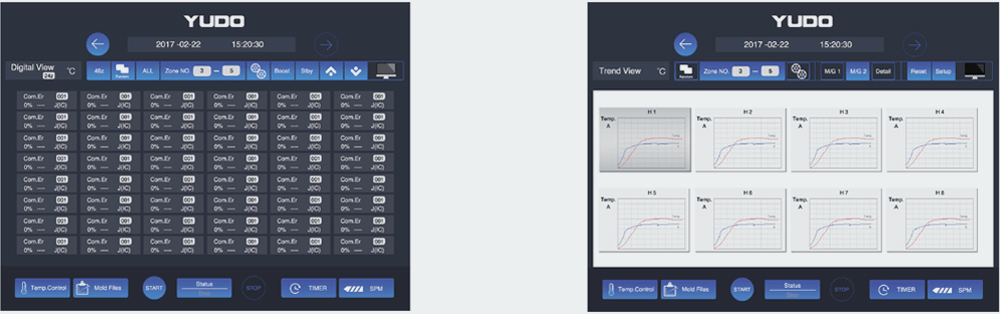

3. It adopts a color touch screen with an integrated interface, and has a precise and stable control system;

4. The operation is simple and easy to understand, users can learn and operate in a short time.

Feature

1. High-precision, high-speed PID control system, suitable for various injection molding environments;

2. Multi-function user selection;

3. Accurately record power consumption and equipment operation,

4. In order to fully grasp the use of equipment, and can accurately calculate the cost.

English

English 中文简体

中文简体 عربى

عربى

.png)